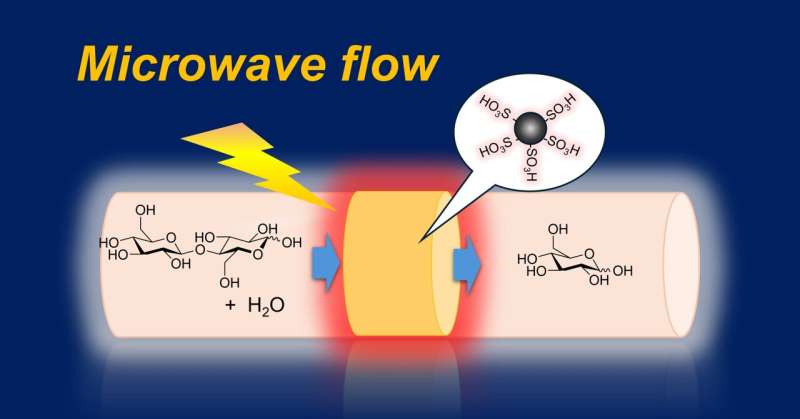

Researchers at Kyushu University have developed a device that combines a catalyst and microwave flow reaction to efficiently convert complex polysaccharides into simple monosaccharides. The device utilizes a continuous-flow hydrolysis process, where cellobiose—a disaccharide made from two glucose molecules—is passed through a sulfonated carbon catalyst that is heated using microwaves. The subsequent chemical reaction breaks down cellobiose into glucose. Their results are published in the journal ACS Sustainable Chemistry & Engineering.

Converting biomass into useful resources has been a topic of scientific research for decades. Biomass polysaccharides, long-chain complex sugars which are ubiquitous in nature, are considered to be one of the more promising substances for efficient conversion since they can be converted into simple sugars that, in turn, can be used in food, pharmaceuticals, and chemical synthesis.

Hydrolysis is one of the more efficient chemical reactions that convert long chain sugars into simple sugars, usually using acids as catalysts. While many acid catalysts are in gas or liquid form, solid acid catalysts—which, as the word describes, is an acid in solid form—are known to be more recyclable and thus have been a point of focus for researchers.

However, solid acid catalysts require high temperatures for them to react efficiently. To overcome this, Associate Professor Shuntaro Tsubaki from Kyushu University’s Faculty of Agriculture and his team investigated applying microwave flow reactions to heat the solid catalysts during the reaction process.

“Microwaves form a localized high-temperature reaction field on the solid catalyst, which can lead to higher catalytic activity while keeping the overall reaction system at a lower temperature,” explains Tsubaki. “In addition, we can have the substrate flow continuously through the reaction vessel where microwaves are applied to the catalyst, resulting in higher yields of the desired product.”

The device the researchers developed utilized a solid acid catalyst composed of sulfonated carbon. Cellobiose, a disaccharide, was used as a model sugar substrate to test the system. In their device, a solution of cellobiose would be passed through the sulfonated carbon catalyst that was heated to up to 100–140℃ using microwaves. The catalyst would then break apart the cellobiose through hydrolysis and produce the monosaccharide glucose.

One of the keys to the system’s efficiency is its ability to separate the microwave‘s electric and magnetic fields.

“Microwaves produce both electric and magnetic fields. The electric field causes the heating of dipolar materials like water. This is what heats up your food. The magnetic field, on the other hand, induces heating of conductive materials like metals and carbon,” says Tsubaki.

“In our device we were able to increase catalytic activity by separating the two fields, then using the electric field to heat the liquid solution of cellobiose and at the same time use the magnetic field to heat up the catalyst.”

Microwave-accelerated catalytic reactions have been applied for a variety of chemical reactions, including organic synthesis, plastics recycling, and biomass conversion. The team hopes that as renewable energy sources continue to surge, electricity-driven chemical production such as theirs will help move the industry toward a greener future.

“We expect our system will help in the development of more sustainable chemical synthesis. We would also like to explore the utility of our methodology on the hydrolysis of other polysaccharides as well as in proteins for the production of amino acids and peptides,” concludes Tsubaki.

More information:

Shuntaro Tsubaki et al, Efficient Cellobiose Hydrolysis over a Sulfonated Carbon Catalyst in a Spatially Separated Microwave Electric- and Magnetic-Field Flow Reactor, ACS Sustainable Chemistry & Engineering (2024). DOI: 10.1021/acssuschemeng.4c07690

Provided by

Kyushu University

Citation:

New device harnesses microwave flow reaction to convert biomass into useful sugars (2025, January 10)

retrieved 10 January 2025

from https://phys.org/news/2025-01-device-harnesses-microwave-reaction-biomass.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.