A team of scientists at UNSW Sydney have developed a highly sensitive miniature sensor that is able to detect low levels of the toxic gas nitrogen dioxide (NO2). The tiny, flexible sensor can detect the harmful gas in real-time without requiring an external energy source.

Gas sensors have a wide range of uses, particularly in health and safety regulations, monitoring the presence of combustible, flammable and toxic gases.

The sensor, which is approximately 2cm x 2cm and just 0.4mm thick, has the potential to overcome some of the existing limitations of gas sensors, including their restrictive size, high cost and energy consumption.

This new prototype, which was developed by Ms. Jiyun Kim, Dr. Tao Wan, Dr. Long Hu, Professor Dewei Chu and a team from UNSW’s School of Materials Science and Engineering has a high sensitivity to NO2 and can run at room temperature.

The latest study, published in Advanced Science, also outlines how key components of the sensor have been sustainably produced using sophisticated printing techniques.

“It’s exciting because it’s not just science for the sake of science—this has great potential to apply to practical uses,” says Prof. Chu.

“The fact that it’s sustainable and has shown excellent performance makes it feel like we’re contributing to revolutionizing gas sensors that can be implemented in wearable sensing applications and large-scale production.”

What are gas sensors used for?

Gas sensors are widely used for different purposes. Most commonly, they are used for health and safety purposes, such as to detect dangerous levels of toxic gases, including carbon monoxide (CO) and NO2. Levels of NO2 can be particularly high in areas with many sources of emissions, including busy roads, factories, and power plants.

“Other gas sensors include those in car engines, which detect oxygen levels,” says Prof. Chu. “This is because you need to tune the ratio of the fuel and oxygen to get a good efficiency.

“They are also used in health care settings, such as to identify the composition of people’s breath.”

However, there are some limitations to these existing sensors, including size and the high energy consumption they are required to run, as well as limited sensitivity and degradation of the sensor over time.

“Current gas sensors can be complex, which also means they can be quite expensive,” says Prof. Chu. “For example, the oxygen sensor in our glove boxes can cost $US 5,000 each.”

To address these challenges, there is a need for continuing research and development to improve their accuracy, reliability, and versatility. So, Prof. Chu and his team set out to create a lightweight, affordable sensor to detect NO2.

2D-printing as a sustainable production technique

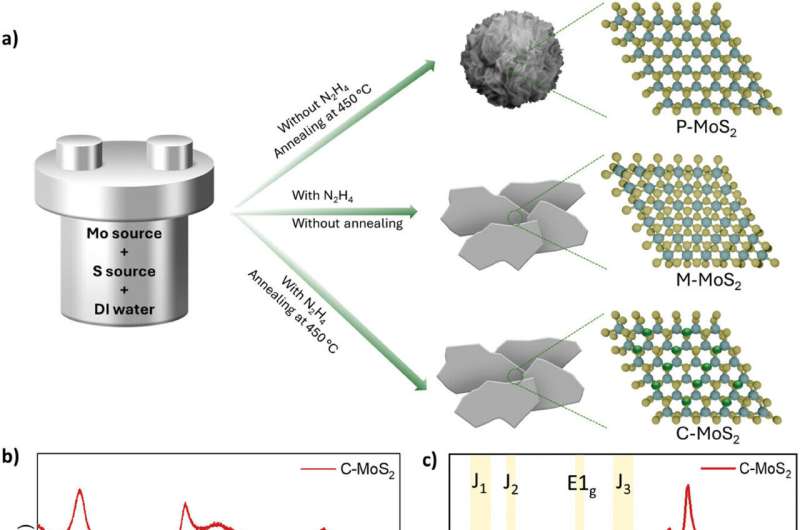

The team started their investigation with a well-known, promising compound that has previously been used for sensing applications due to its sustainability and biocompatibility: molybdenum disulfide (MoS2).

“My research group has been researching the potential of MoS2 as a sensing device for over eight years,” says Prof. Chu.

“There are two different subgroups of MoS2, one that is more conductive—meaning it is better at conducting electricity—and one that is less conductive.

“We found that combining the two subgroups makes the best gas sensor compound, keeping it conductive—which is essential for these sensors—while also sensitive to external gas composition.”

After combining the two subtypes of MoS2, the team made several additional changes to the soluble compound. “For example, we also added nitrogen to the soluble mixture, to increase its sensitivity,” says Prof. Chu.

When an NO2 molecule scratches the surface, the MoS2 compound has the capacity to absorb that molecule. “In capturing the NO2 molecules, the surface electrical resistance is altered, and we can then register a change of the conductivity at room temperature.”

What’s even more unique about this mini sensor is that it has been constructed using 2D-printing technology.

“2D-printing technology is similar to 3D-printing, except that it happens on a very fine surface to minimize the sensor production costs,” says Prof. Chu. “The process involves having small nodules which inject soluble materials onto a flat surface.”

The team used this 2D-printing to build two components of the sensor. “We actually print out the conductive nano materials using 2D-printing, which act as our sensor electrodes,” says Prof. Chu. “We then print the sensor material itself, which is the MoS2 that we developed in the lab.”

Promising initial results

Existing commercial gas sensors encounter critical issues that limit their development and various applications due to their high energy consumption, low accuracy, slow real-time monitoring, and lack of ability to detect trace concentration.

“The principle of the current gas sensors on the market is that they have to be heated up, sometimes up to 300°C, otherwise they cannot detect,” says Prof. Chu. “Because our device can work at room temperature, it requires far less energy.”

Testing in the lab found that their MoS2-based sensor had a high sensitivity of 10ppm NO2—this means the sensor is able to successfully detect 10 particles of NO2 in 1 million gas particles.

While NO2 exists naturally in very small quantities in the air, the main source is human activity, such as from burning coal, and high levels of the gas are a danger to human life. Concentration of 50–100ppm NO2 could cause delayed lung injury and more than 200ppm is considered an immediate danger to life.

Next-gen gas sensing technology

Thanks to its miniature size and low energy consumption, the wearable device has a wide scope of uses, particularly when it comes to safely measuring gas concentrations in different working environments.

“We hope to work on designing wearable sensing devices for monitoring air quality, such as for industrial safety systems at mining sites, or in warehouses, where concentrations of NO2 can be particularly high,” says Prof. Chu.

While this development represents a big step in next-generation gas sensor technology, Prof. Chu explains that there are still improvements to be made, such as testing sensitivity to other gases, which in turn, will broaden the scope of its potential uses.

“We have limited access to a wider range of gases, such as volatile organic compounds or other toxic gases, like ozone3 or CO, due to safety issues,” he says. “It would be great if we could test a broader range of gases to evaluate how our sensor can work towards other target gases.”

More information:

Jiyun Kim et al, Synergetic Phase Modulation and N‐Doping of MoS2 for Highly Sensitive Flexible NO2 Sensors, Advanced Science (2024). DOI: 10.1002/advs.202410825

Provided by

University of New South Wales

Citation:

Miniature sensor that detects toxic gas shows promising results in the lab (2024, December 20)

retrieved 22 December 2024

from https://phys.org/news/2024-12-miniature-sensor-toxic-gas-results.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.