Catalysts belonging to the zeolite family help to remove toxic nitrogen oxides from industrial emissions. Researchers at the Paul Scherrer Institute PSI have now discovered that their complex nano porous structure is crucial. Specifically, individual iron atoms sitting in certain neighboring pores communicate with each other, thereby driving the desired reaction.

Industry produces gases that are harmful to both humans and the environment and therefore must be prevented from escaping. These include nitric oxide and nitrous oxide, the latter also known as laughing gas. Both can be produced simultaneously when manufacturing fertilizers, for example.

To remove them from the waste gases, companies use zeolite-based catalysts. Researchers at the Paul Scherrer Institute PSI, in collaboration with the Swiss chemical company CASALE SA, have now worked out the details of how these catalysts render the combination of these two nitrogen oxides harmless.

The results of their research have been published in the journal Nature Catalysis and provide clues as to how the catalysts could be improved in the future.

An entire zoo of iron species

“The Lugano-based company CASALE contacted us because they wanted to develop a better understanding of how their catalysts used for the abatement of nitrogen oxide actually work,” says Davide Ferri, head of the Applied Catalysis and Spectroscopy research group at the PSI Center for Energy and Environmental Sciences.

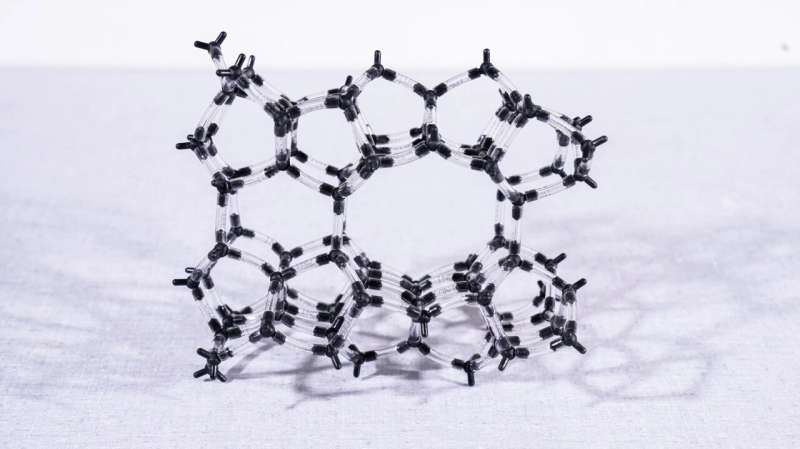

The zeolites used for this are composed of aluminum, oxygen and silicon atoms forming a kind of framework. Zeolites occur naturally—as minerals in rock formations, for example—or they can be manufactured synthetically. Many catalysts used in the chemical industry are based on these compounds, with additional elements added to the basic structure depending on the specific application.

When the zeolite framework also contains iron as an active substance, it enables the conversion of the two nitrogen oxides, nitric oxide (NO) and nitrous oxide(N2O), into harmless molecules. “However, these iron atoms can be located in many different positions of the zeolite framework and can possess various forms,” says Filippo Buttignol, a member of Ferri’s group. He is the principal author of the new study, which he conducted as part of his doctoral thesis.

“The iron can lodge in the small spaces of the zeolite in the form of single atoms, or else several iron atoms can be bound together and with oxygen atoms in slightly larger spaces in the regular lattice as diatomic, multiatomic or polyatomic clusters.” In short, the catalyst contains an entire zoo of different iron species. “We wanted to know which of these iron species is actually responsible for the catalysis of nitrogen oxides.”

The researchers, who specialize in spectroscopic analyses, knew exactly which three types of experiment they needed to carry out to answer this question. They performed these while the catalytic reaction was taking place in their zeolite sample.

First they used the Swiss Light Source SLS at PSI to analyze the process using X-ray absorption spectroscopy. “This allowed us to look at all the iron species simultaneously,” explains Buttignol.

Next, in collaboration with ETH Zurich, they used electron paramagnetic resonance spectroscopy to identify the contribution of each species. And finally—again at PSI—the scientists used infrared spectroscopy to determine the molecular aspect of the different iron species.

Catalysis happens at individual but communicating atoms

Each of these three methods contributed a piece of the puzzle, eventually leading to the following overall picture: Catalysis takes place at single iron atoms which are located in two very specific, neighboring sites of the zeolite lattice. During the process, these two iron atoms act in concert with each other.

One of them, sitting at the center of four oxygen atoms in the zeolite arranged in the form of a square and responsible specifically to convert nitrous oxide, communicates with a different iron atom, which is surrounded by oxygen atoms arranged in the form of a tetrahedron and at which the nitric oxide reacts.

“Only where this precise arrangement is found do we see iron contributing to the catalysis of the simultaneous abatement of the two gases,” says Buttignol. Each of these iron atoms gave up an electron and took it back again, in other words, the typical redox reaction of catalysis took place there over and over again.

Removing hazardous nitrogen oxides more efficiently

Ferri concludes, “If you know exactly where the chemical reaction takes place, you can start adjusting the manufacture of catalysts accordingly.”

The catalysis of nitric oxide and nitrous oxide and thus their removal from industrial waste gases is important because both are toxic to humans. Beyond this, both gases are also harmful to the environment: nitric oxide is one of the causes of acid rain, while nitrous oxide has such a strong impact on the climate that one molecule of it contributes almost 300 times more to the greenhouse effect than a molecule of carbon dioxide.

More information:

Filippo Buttignol et al, Iron-catalysed cooperative redox mechanism for the simultaneous conversion of nitrous oxide and nitric oxide, Nature Catalysis (2024). DOI: 10.1038/s41929-024-01231-3

Provided by

Paul Scherrer Institute

Citation:

Spectroscopy study determines how catalysts remove dangerous nitrogen oxides (2024, October 10)

retrieved 11 October 2024

from https://phys.org/news/2024-10-spectroscopy-catalysts-dangerous-nitrogen-oxides.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.