For the first time, a team of researchers at Lawrence Livermore National Laboratory (LLNL) quantified and rigorously studied the effect of metal strength on accurately modeling coupled metal/high explosive (HE) experiments, shedding light on an elusive variable in an important model for national security and defense applications.

The team used a Bayesian approach to quantify metal strength uncertainty with tantalum and two common explosive materials and integrated it into a coupled metal/HE model. Their findings could lead to more accurate models for equation-of-state-studies, which assess the state of matter a material exists in under different conditions. Their paper—featured as an editor’s pick in the Journal of Applied Physics—also suggested that metal strength uncertainty may have an insignificant effect on result.

“There has been a long-standing field lore that HE model calibrations are sensitive to the metal strength,” said Matt Nelms, the paper’s first author and a group leader in LLNL’s Computational Engineering Division (CED). “By using a rigorous Bayesian approach, we found that this is not the case, at least when using tantalum.”

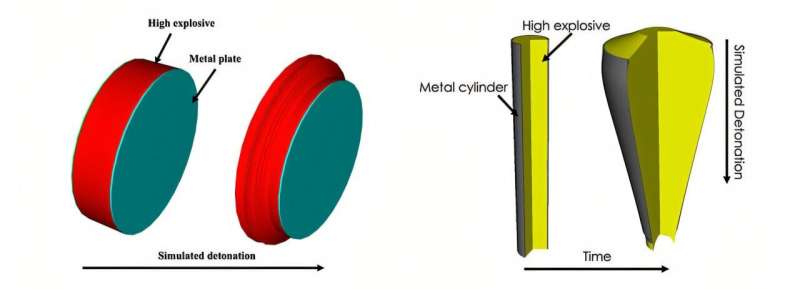

In a coupled metal/HE experiment, the HE material is attached to a metal and then detonated. Researchers then measure the velocity of the metal’s surface to infer the HE’s behavior as it transitions from solid to gas.

Like in many experiments, computer models help HE researchers understand behaviors and design tests to achieve the best results possible. Making models accurate involves understanding the range of possible behaviors of different variables, known as uncertainties, and how all these little variances may add up to impact an experiment’s results. The more well-understood the uncertainties, the better researchers can introduce this knowledge to the model to help it make accurate predictions.

The strength of the metal—its ability to withstand forces—is the hardest uncertainty to quantify, as the extreme conditions and dynamic motion caused by the detonation make it difficult to separate from the HE’s behavior. The team used a Bayesian framework to tackle this problem. Bayesian analysis relies on probability to determine the likely causes of a given effect; in this case, predicted results.

“The beauty and challenge of the Bayesian framework is that it is naïve to the physics,” said Nelms. “This means it takes a lot of care to make sure the results make physical sense but also provides a tool that is less biased.”

The team analyzed results from three types of common configurations with tantalum metal: two plate tests, where the HE (LX-14 or LX-17) pushes a thin metal disk, and a cylinder test, where the HE (LX-17) expands a metal cylinder that confines it. The Bayesian analysis looked at posterior probabilities, the distribution of likely outcomes, first incorporating metal strength uncertainty and then ignoring it. The differences between the posteriors provided a good estimation of metal strength uncertainty and showed the effect it had on results.

Nelms emphasizes that the results are not yet transferrable to other metals, but that the approach can be. He hopes further research can build on their findings to both shed light on their discovery and help make HE models more accurate to support national security.

More information:

Matthew Nelms et al, Uncertainty quantification of material parameters in modeling coupled metal and high explosive experiments, Journal of Applied Physics (2024). DOI: 10.1063/5.0226642

Provided by

Lawrence Livermore National Laboratory

Citation:

Quantifying metal strength uncertainty in high-explosives models (2025, February 3)

retrieved 3 February 2025

from https://phys.org/news/2025-02-quantifying-metal-strength-uncertainty-high.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.