A study appearing in Proceedings of the National Academy of Sciences introduces a trimetallic catalyst—including nickel (Ni), copper (Cu), and zinc (Zn) nanoparticles supported on defective ceria (CeO2)—that achieves unprecedented performance in CO2 reduction.

The catalyst demonstrated remarkable CO productivity of 49,279 mmol g⁻¹ h⁻¹ at 650°C, a nine-fold increase over previously reported catalysts. It displayed CO selectivity of up to 99%, and maintained a stable performance for at least 100 hours without degradation.

The catalyst’s extraordinary efficiency is attributed to the creation of a strong metal-support interaction (SMSI) between the trimetallic sites and the defective ceria. This unique interaction fine-tunes the electronic structure, enabling optimal performance.

The conversion of CO2 to CO is a critical step in transforming carbon dioxide into value-added chemicals and fuels. However, commercial viability has been hindered by low productivity, poor selectivity, and instability of existing catalysts. By leveraging SMSI and defect engineering, this study has overcome these barriers, setting new benchmarks in CO2 reduction catalysis.

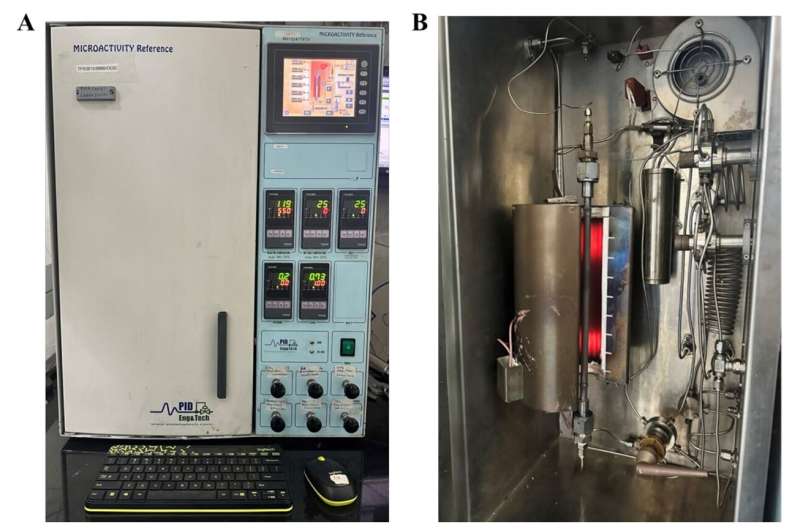

This research relied heavily on advanced in-situ techniques and a multidisciplinary collaboration.

Dr. Pieter Glatzel and the team at the European Synchrotron Radiation Facility (ESRF), Grenoble, played a pivotal role in uncovering the electronic dynamics of the system. High-energy-resolution fluorescence-detection X-ray absorption spectroscopy (HERFD-XAS) revealed how SMSI alters oxidation states and electron density distribution across the catalyst.

Dr. Paul Paciok from the Ernst-Ruska Center, Germany, contributed critical insights through in-situ transmission electron microscopy (TEM) and electron energy loss spectroscopy (EELS). These studies visualized, for the first time, the growth and movement of trimetallic sites under catalytic conditions. Once SMSI was established, the movement ceased, preventing further diffusion or sintering.

Prof. Ojus Mohan’s group at IIT Bombay utilized density functional theory (DFT) calculations to unravel the reaction mechanism. The studies highlighted how reaction intermediates form and convert into products, driven by a complex interplay of direct dissociation and redox pathways on different active sites.

This research not only provides a highly effective catalyst for CO2 conversion but also offers a blueprint for designing next-generation catalysts through precise electronic structure tuning and defect manipulation.

These findings open new avenues for the development of advanced catalysts for CO2 utilization and other critical chemical transformations.

Last author Prof. Polshettiwar states, “By combining traditional catalytic materials with cutting-edge defect engineering and SMSI, we’ve shown how to address fundamental limitations in catalysis. The study offers a roadmap for designing advanced catalysts and demonstrates the impact of integrating traditional materials with cutting-edge approaches, offering hope for a sustainable future.”

More information:

Charvi Singhvi et al, Tuning the electronic structure and SMSI by integrating trimetallic sites with defective ceria for the CO2 reduction reaction, Proceedings of the National Academy of Sciences (2025). DOI: 10.1073/pnas.2411406122

Provided by

Tata Institute of Fundamental Research

Citation:

Trimetallic synergy and defects: A catalyst for climate action (2025, January 27)

retrieved 27 January 2025

from https://phys.org/news/2025-01-trimetallic-synergy-defects-catalyst-climate.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.