Takeout containers get your favorite noodles from the restaurant to your dining table (or couch) without incident, but they are nearly impossible to recycle if they are made from foil-lined plastics. Research published in ACS Omega suggests that replacing the plastic layer with paper could create a more sustainable packaging material. The researchers used mechanical demonstrations and computer simulations to identify paper-aluminum laminate designs that won’t compromise on performance.

Protective packaging, like containers made from polyethylene and aluminum laminates, combines the strength and durability of plastic with the moisture- and light-blocking properties of aluminum foil. While these materials are effective, there’s been a shift toward consumers desiring less plastic and more environmentally friendly materials in the packaging that comes into their homes.

To create such an option for protective packaging without sacrificing functionality, Hamed Zarei and colleagues designed a variety of paper-aluminum laminates and compared their strength and durability to common polyethylene-aluminum packaging.

First, Zarei’s team manufactured two paper-aluminum laminates:

- A machine-direction (MD) laminate made from aluminum and paper with fibers that run parallel to the direction of machine loading (with the grain).

- A cross-direction (CD) laminate made from aluminum and paper with fibers that run perpendicular to the direction of machine loading (against the grain).

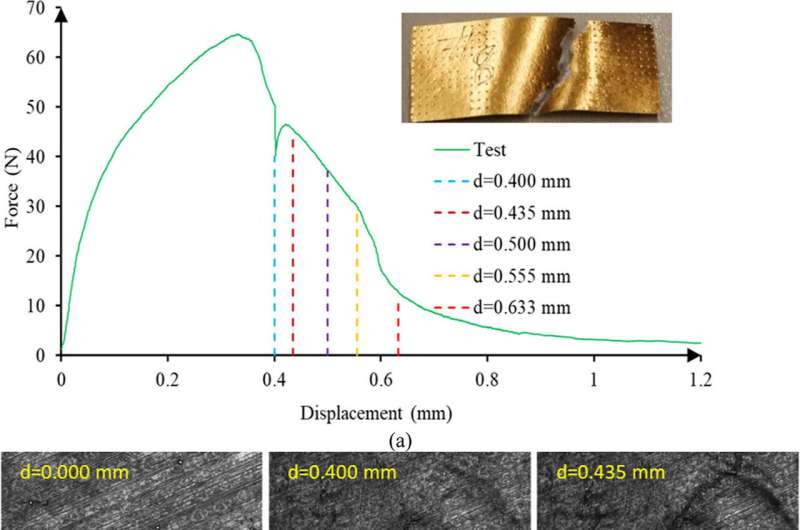

The researchers then compared the tensile strength of MD and CD paper-aluminum laminates to polyethylene-aluminum laminate by stretching samples of each material with gradually increasing force on laboratory machines. They also created a digital model, verified with their tensile strength data, that could replicate these laminate stretching tests and reliably predict the material’s response under different scenarios.

In tensile strength tests, the polyethylene-aluminum laminate could be stretched further without breaking than both paper-aluminum laminates. And of the two paper-containing materials, the one made from MD paper could be stretched further but formed cracks along the paper’s grain faster than the CD paper.

By running simulations of the MD, CD and a mixed MD/CD paper on their digital model, the researchers predicted that an aluminum film paired with a paper layer made from both MD and CD fibers would result in mechanical properties nearly identical to conventional polyethylene-aluminum laminate.

While they haven’t yet created the MD/CD paper-aluminum laminate in the lab, the researchers say this study provides packaging engineers with information to create sustainable materials that could perform like conventional options.

More information:

Hamed Zarei et al, Digital Twin Model of Paper–Aluminum Laminates for Sustainable Packaging, ACS Omega (2024). DOI: 10.1021/acsomega.4c05798

Provided by

American Chemical Society

Citation:

Paper-aluminum combo can replace plastic for strong, sustainable packaging (2024, October 31)

retrieved 31 October 2024

from https://phys.org/news/2024-10-paper-aluminum-combo-plastic-strong.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.