Researchers at the Indian Institute of Science Education and Research (IISER) Pune and the CSIR-National Chemical Laboratory (NCL) Pune have shown that the macroscopic deformation of amorphous solids is controlled by structural defects within the material.

This joint effort, led by Dr. Vijayakumar Chikkadi at IISER Pune and Dr. Sarika Bhattacharyya at CSIR-NCL, Pune, combines experimental studies on colloidal glasses—model systems for amorphous solids—with a theoretical framework based on the structural order parameter.

Published in the Proceedings of the National Academy of Sciences, the findings address a long-standing question in materials science and condensed matter physics.

All materials deform when external stresses are applied. In 1934, G.I. Taylor, M. Polanyi, and E. Orowan independently explained that macroscopic deformation originates from the dynamics of defects within the material. In crystalline solids, identifying these defects is relatively straightforward due to lattice distortions.

However, in amorphous solids, the lack of long-range order makes detecting defect-like regions far more challenging. While several approaches have been proposed to identify soft, defect-like regions in disordered solids, direct observation in experimental systems has been difficult.

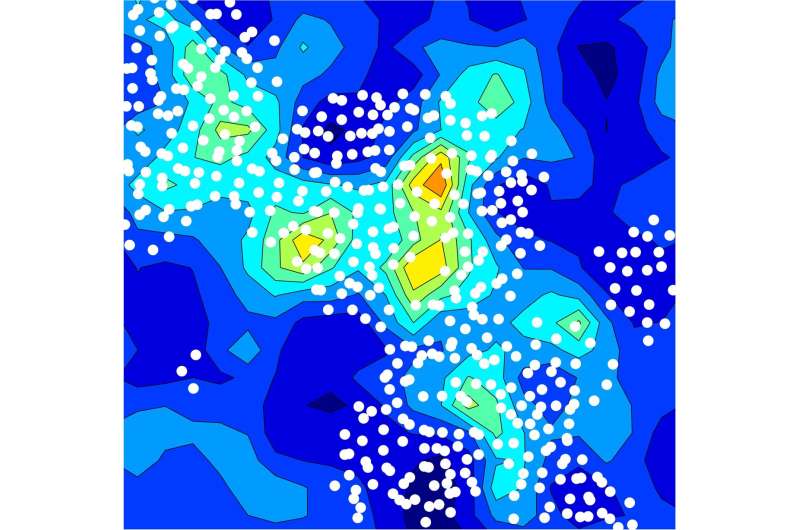

To address this, Ratimanasee Sahu and Dr. Vijayakumar Chikkadi from IISER Pune conducted experiments using dense colloidal suspensions, which serve as models of amorphous solids. By tracking the motion of nearly 100,000 individual colloidal particles in three dimensions over time, using advanced microscopy techniques, they obtained unprecedented access to microscopic information that is difficult to acquire in atomic systems.

These studies exploited the structural order parameter developed by Mohit Sharma and Dr. Sarika Bhattacharyya at CSIR-NCL, Pune, to quantify soft and hard regions in amorphous suspensions, leading to the identification of structural defects.

“A key advantage of this order parameter, which is developed from detailed microscopic theory, is its practical applicability in experimental settings, making it more accessible compared to other theoretical quantities,” said Dr. Sarika Bhattacharyya.

For the first time, the team experimentally demonstrated that macroscopic deformation in colloidal glasses originates from localized deformations, which occur preferentially in regions containing structural defects when subject to external stress.

“This breakthrough significantly deepens our understanding of how defects affect the mechanical properties of disordered solids. It also paves the way for developing improved rheological models based on structural aspects that are applicable to a wide range of materials, including soft matter like granular materials and emulsions, as well as metallic glasses,” said Dr. Vijaykumar Chikkadi speaking on the future prospects of this work.

More information:

Ratimanasee Sahu et al, Structural origin of relaxation in dense colloidal suspensions, Proceedings of the National Academy of Sciences (2024). DOI: 10.1073/pnas.2405515121

Citation:

Key role of structural defects in amorphous solid deformation uncovered (2024, October 18)

retrieved 18 October 2024

from https://phys.org/news/2024-10-key-role-defects-amorphous-solid.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.